WHAT IS THE DIFFERENCE BETWEEN INDUSTRIAL AND HOME COMPOSTING?

WHAT IS THE DIFFERENCE BETWEEN INDUSTRIAL AND HOME COMPOSTING?

Nowadays we often hear about “compostable” packaging. Since the environment has become a priority for a growing number of consumers, Companies more and more use this word to place their products as Eco-Friendly.

WHAT DOES “COMPOSTABLE” REALLY MEAN AND HOW DOES COMPOSTING WORK?

Compostable products are made of “natural” materials and degrade entirely without producing toxic residues. The process must be at pre-established levels and within a defined length of time. In order to be classified as Compostable, they must meet specific requirements define in the European standard EN 13432.

Thus, Composting is a process that breaks down matter to create a nutrient-rich “compost”.

This compost can be used as a powerful fertilizer and soil conditioner.

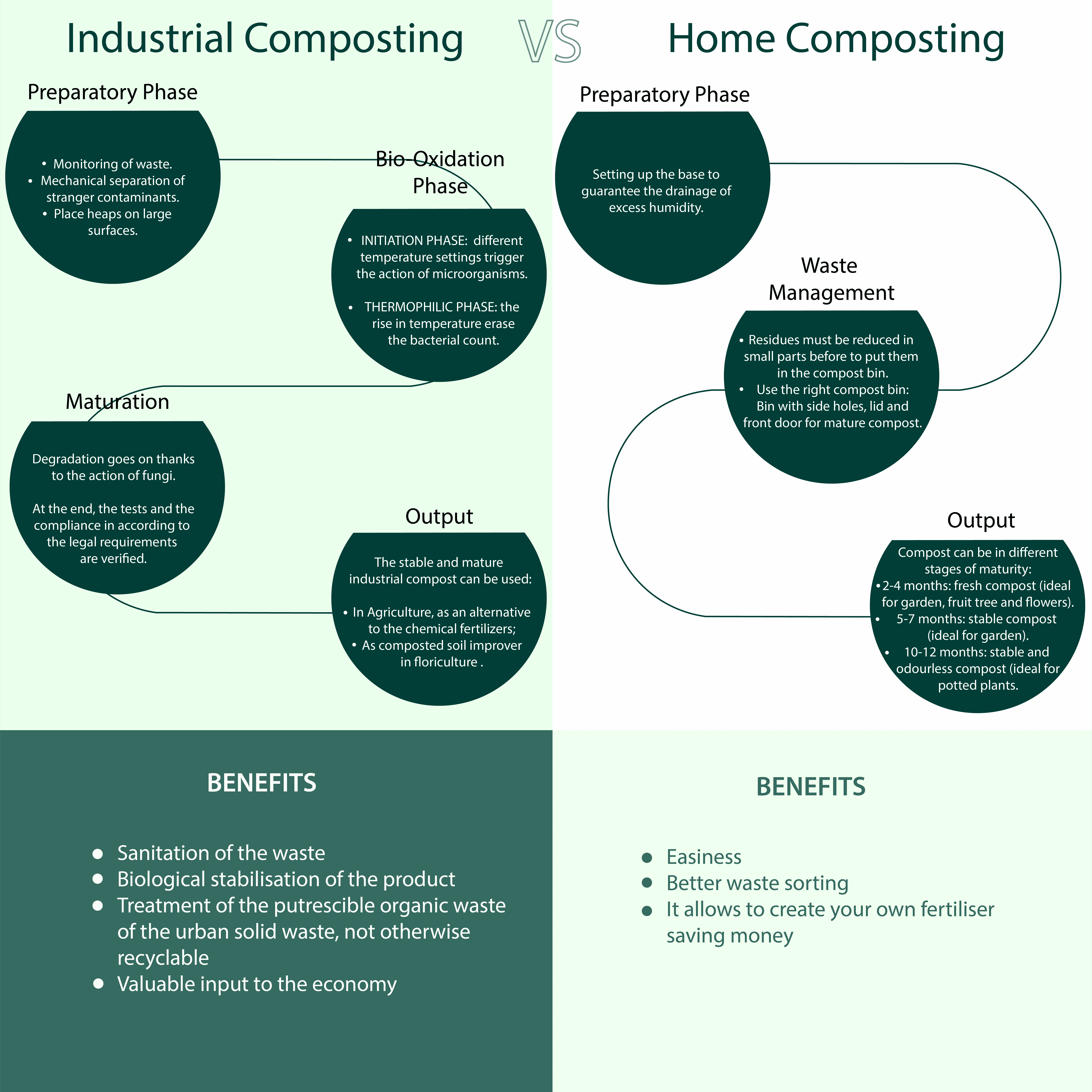

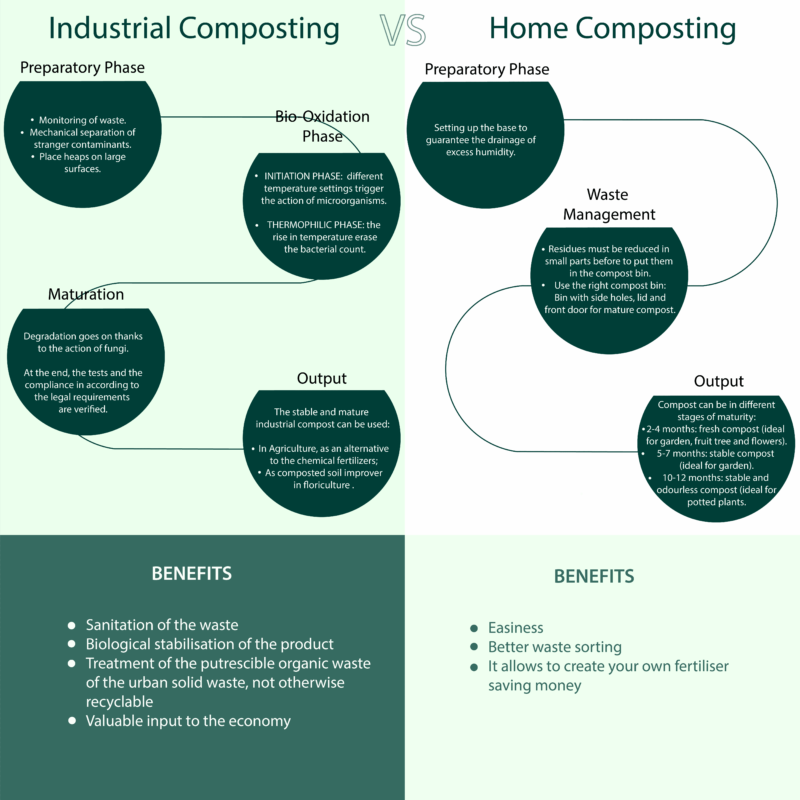

INDUSTRIAL COMPOSTING VS HOME COMPOSTING

Composting offers a closed-cycle solution but the proper disposal of organic waste is crucial to avoid unnecessary contributions to landfill.

We distinguish between “industrial composting” and “home composting”, depending on the setting and conditions required for the decomposition of the products. At the end of the process, both types of composting develop a compost rich in nutrients.

INDUSTRIAL COMPOSTING

Multi-step and carefully tracked composting process with measured inputs of heat, humidity and oxygen. An industrial composting plant optimizes the process to ensure a fast biodegradation of organic materials by checking on:

- The conditions of the shredding of the material to the same size;

- The temperature and oxygen levels.

In this way, the production of a high quality and free of toxic substances compost is guaranteed.

Now, organic waste (including packaging) is converted into stable and sanitized products that can be used in agriculture.

When the packaging is disposed in an industrial composting plant, it is treated with temperature higher than the one you have in the compost bin. The higher levels of heat in a highly controlled environment and with specific conditions further break the packages, speed up the decomposition (a few months) and ensure a better stability/quality of the compost.

HOME COMPOSTING

Home composting produces nutrient-rich soil thanks to the breakdown of organic waste such as food scraps, grass clippings, etc. This occurs over a period of several months (about a year) in a home compost bin or landfill. However, the conditions and temperatures (lower heat for a longer time) of home composting are unable to decompose some packaging materials.

In order to compost at home, the packaging must be certified for this purpose (inks and adhesives included).

WHY DO COMPOST CERTIFICATIONS MATTER?

Once you know the difference between industrial and home composting, it is important to assess whether packaging have the certifications to ensure they are actually compostable. The ordinary labeling of a “compostable” product does not specify how a product can be composted (it may only be able to decompose in an industrial plant or have components such as inks and adhesives that adversely affect the quality of the compost).

Make sure the packaging is certified so that you always know how to proper dispose them and responsibly compost them.